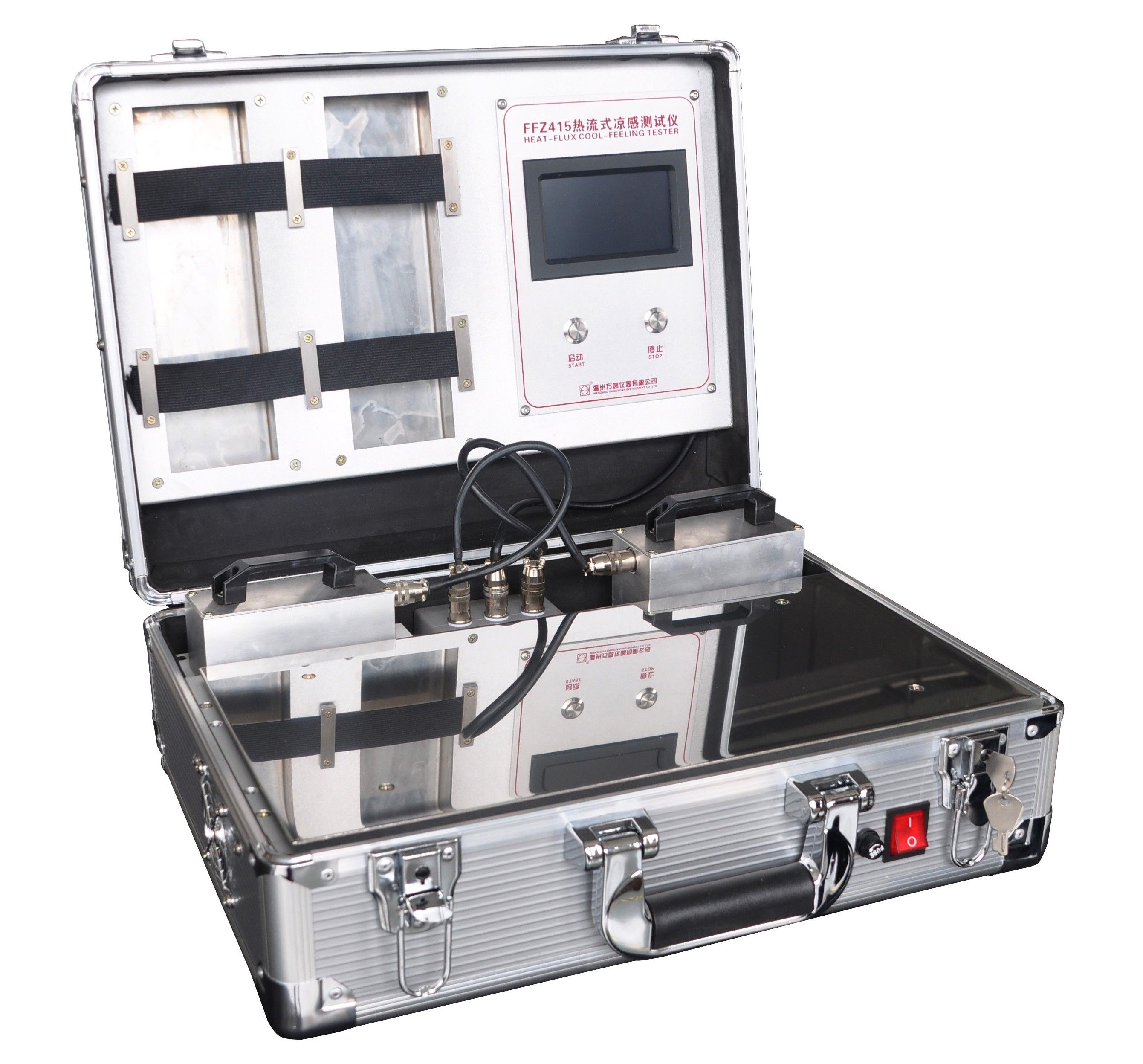

On April 27, 2017, China Federation of Textile Industries organized and held an appraisal meeting on key technology projects for the production of high thermal conductivity chemical fiber filaments and their new cool fabrics (see Figures 1 and 2). Among them, the fast response FFZ415 heat flow fabric cooling tester developed by our company and the military supplies research institute of the general logistics department for testing the cooling performance of cooling fabrics ( see fig. 4 for the overall appearance of the machine with relevant patents obtained ) has been highly affirmed and praised by the appraisal experts. The project passed the appraisal smoothly, and the comprehensive evaluation was: national advanced (see fig. 3).

Site 1 of the appraisal meeting (Figure 1)

Site 1 of the appraisal meeting (Figure 2)

Site 1 of the appraisal meeting (Figure 3)

FFZ415 heat flow fabric cooling tester physical diagram (fig. 4)

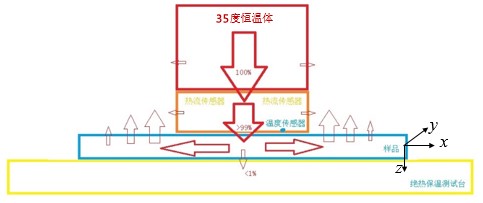

Principle figure (fig.5)

35 ℃ constant temperature heat source body simulates human body. When the temperature of the thermostatic body is higher than the ambient temperature ( i.e. the surface temperature of the fabric ), the heat of the thermostatic body is conducted to the fabric through a heat flux meter with a certain heat flux density, and is conducted out along the vertical direction and the plane direction of the fabric, i.e. XYZ three directions. When the fabric is placed on the insulating foam board, after the fabric absorbs enough heat, the heat flow will be conducted along the plane direction with good thermal conductivity, namely xy direction, and further heat exchange will be conducted through conduction, radiation, convection and environment.

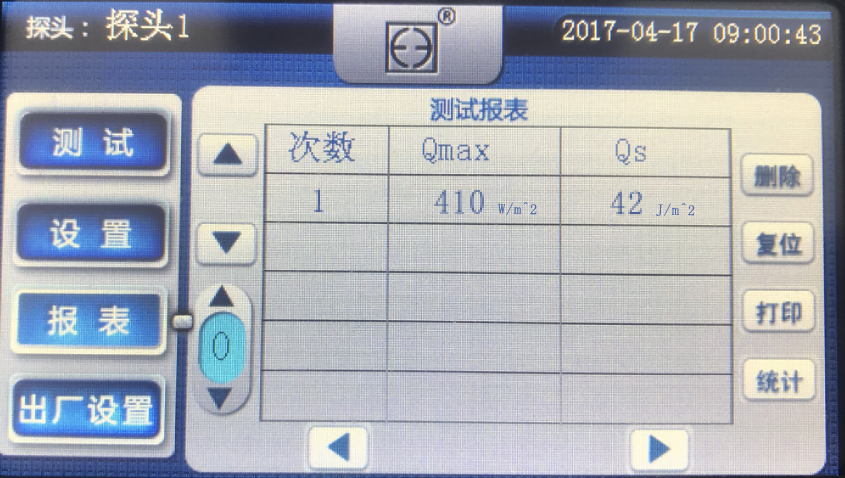

FFZ415 Heat Flow Fabric Cold Sense Tester Color Touch Screen Test Interface

Interface 1 (figure 6)

Interface 2 (figure 7)

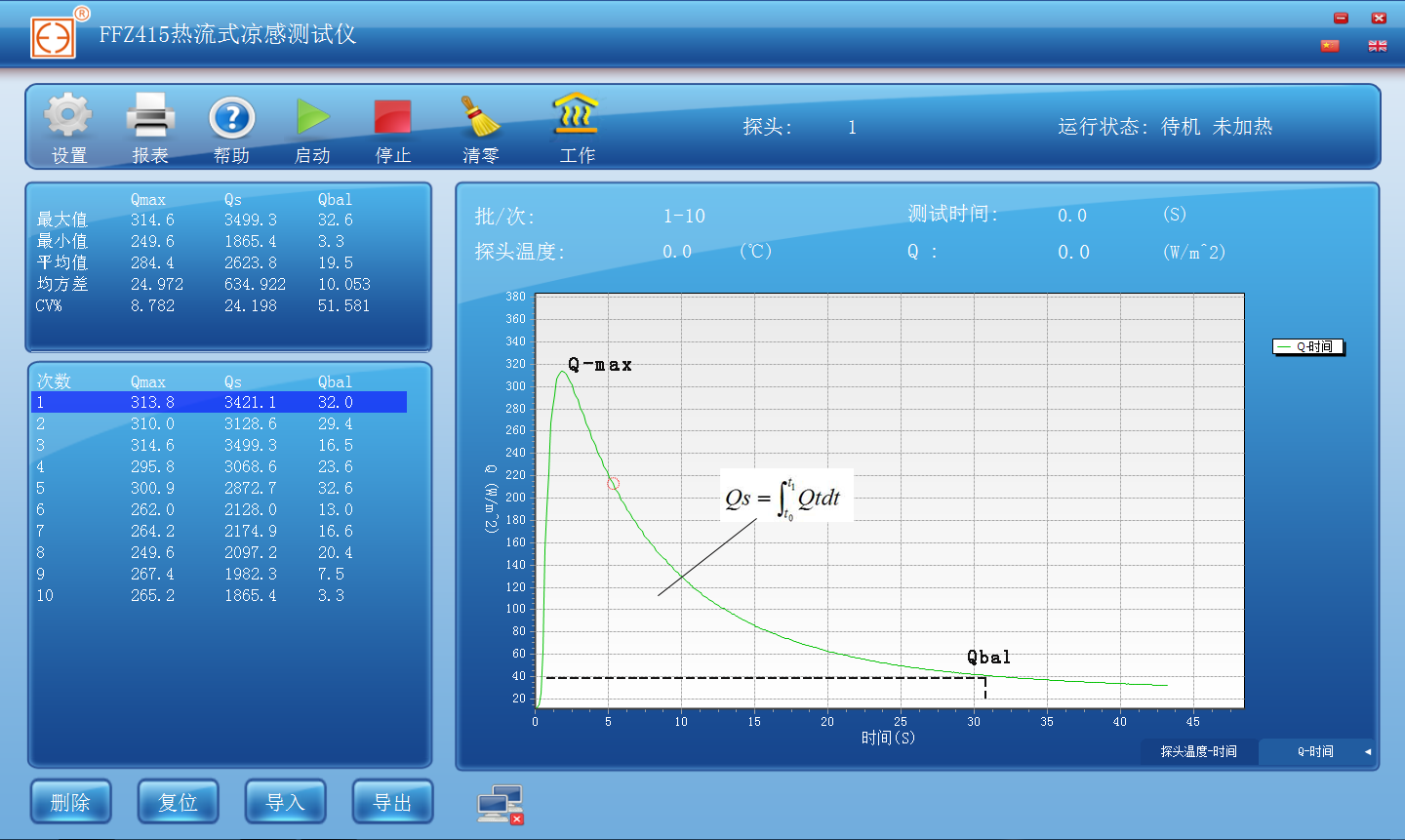

FFZ415 heat flow fabric cooling tester test interface after connecting PC ( fig. 8 )

Working principle of instrument:

When the skin of the human body contacts the fabric, the heat of the human body will be transferred outward through the close-fitting fabric. This instrument is used to examine the tangential heat transfer characteristics of fabrics and other materials. The heat transfer process can be divided into two stages according to the subjective feeling of human body: first, the skin contacts the fabric and the temperature balance between the two is reached immediately. Human body heat is conducted to the surface of the fabric and along XYZ three directions until the absorption capacity of the fabric is reached ( in the instrument, a constant temperature body of 35 degrees Celsius is used to continuously transfer heat to the sample until the temperature balance is reached to fit the above process ). The second stage is that after the temperature of the human body and the fabric is balanced, the heat will continue to conduct along the xy direction and further exchange heat with the environment through conduction, radiation, convection and other means. This instrument ( the basic principle is shown in fig. 5 ) places a heat flow meter that can detect the heat flow per unit area perpendicular to the heat flow direction under a constant temperature heat source body at 35 ℃ to form a test probe together. The samples were placed on an insulated foam table for testing.

Principle figure (figure 5)

35 ℃ constant temperature heat source body simulates human body. When the temperature of the thermostatic body is higher than the ambient temperature ( i.e. the surface temperature of the fabric ), the heat of the thermostatic body is conducted to the fabric through a heat flux meter with a certain heat flux density, and is conducted out along the vertical direction and the plane direction of the fabric, i.e. XYZ three directions. When the fabric is placed on the insulating foam board, after the fabric absorbs enough heat, the heat flow will be conducted along the plane direction with good thermal conductivity, namely xy direction, and further heat exchange will be conducted through conduction, radiation, convection and environment.

FFZ415 Heat Flow Fabric Cold Sense Tester Color Touch Screen Test Interface

Interface 1 (figure 6)

Interface 2 (figure 7)

FFZ415 heat flow fabric cooling tester test interface after connecting PC (fig. 8)

This instrument can measure three results:

(1) The instantaneous heat flux value Qmax, i.e. the peak value of the curve, reflects the coolness at the moment of contact, with the unit being W/m2 or W/cm2, the greater the Qmax of the fabric, the stronger the coolness of the human body.

(2) Initial heat flux peak area Qs,t0: Heat Transfer Start Time,t1: Time of Heat Balance State,Qt: instantaneous value of heat at time t QUOTE QUOTE,The unit is J/m2 or J/cm2, which indicates the total heat transferred through the unit area within a certain period of time ( from the beginning of heat transfer to the time when the heat balance state is reached ), and comprehensively reflects the heat absorption capacity of the fabric. The larger Qs is, the stronger the heat absorption capacity of the fabric is, and the stronger and lasting the cooling feeling felt by the human body is.

(3) Steady state heat flux Qbal, i.e. the heat flux of equilibrium curve, reflects the thermal conductivity of the fabric along the plane direction and is the inherent property of the material itself, indicating a lasting cool feeling. The larger Qbal is, the stronger the fabric's durable thermal conductivity is. At present, only the FTTSFA019 standard issued by Taiwan is based on the Japanese testing instrument KESF7. At present, the national standard " Testing and Evaluation of Instant Contact Cooling Performance of Textiles" passed by the review meeting held in Xiamen in January 2016 has not been released publicly. The difference between the two standards is: FTTSFA019 refers to KESF7, and the sample is placed on a thermostatic plate; however, the national standard sample is placed on polyethylene foam board with low contact cooling value. Both of them are the same only for measuring the cold feeling at the moment of contact.Compared with similar products, at present there is no instrument for testing the instant cold feeling of contact in China, and only KESF7 made in Japan is available abroad. FFZ415 Heat Flow Cold Sense Tester can not only meet the above two standards, but also fully reflect fabric cold sense from three aspects of initial contact cold sense, fabric heat absorption capability and durable heat conduction capability. The system solves the problems of single test parameters, low probe pressure, difficulty in conforming, poor repeatability and the like existing in the existing KESF7 fabric cool feeling test.