Notes on Development of Textile Far Infrared Temperature Rise Tester;

Wenzhou Fangyuan Instrument Co., Ltd is a leading enterprise in Wenzhou airport new district. He successively obtained 24 national innovation funds, torch program, national key products, provincial and municipal science and technology projects, 14 patents (including 3 invention patents), ISO9001 system certification, CE safety certification, AATCC enterprise members, universal material testing machine measuring instrument manufacturing license, etc. . It has been successively appraised as a national high-tech enterprise, an advanced enterprise in scientific and technological innovation, a three-level enterprise in safety production standardization, a skilled master's workshop, Ouhai famous brand trademark, a national outstanding contribution unit in textile measurement, etc. The company always regards innovation as the core competitiveness of the enterprise and takes the four innovations of product innovation, process innovation, system innovation and service innovation as a whole and consistently implements them. Recently, another cooperative development project between our company and Guangzhou Fiber Product Testing and Research Institute, the far infrared temperature rise test of textiles, passed the acceptance smoothly. The successful research and development of this instrument has solved the testing requirements of the third-party testing organizations and clothing enterprises for product quality.

FFZ411 textile far infrared temperature rise tester

Due to the needs of the testing market, Guangzhou Fiber Product Testing Research Institute decided to carry out the far infrared temperature rise testing of textiles. Because the national standard GB/T301272013 Testing and Evaluation of Far Infrared Properties of Textiles related to this project was promulgated in 2013, at that time, domestic and foreign instrument manufacturers had not yet developed testing instruments that met this standard. Through extensive market research and investigation, Guangzhou Fiber Product Testing Research Institute has decided to cooperate with our company to jointly develop a far infrared temperature rise tester for textiles.

1. In July 2015, Guangzhou Fiber Product Testing Research Institute put forward technical requirements for the project;

2. In September 2015, our company issued a technical plan for the instrument.

3. In October 2015, both parties confirmed the technical scheme of the instrument and signed a development contract.

4. The research and development of the instrument was completed in May 2016 and passed the internal inspection of the quality department of the company.

5. In June 2016, Guangzhou Fiber Product Testing Research Institute delivered the test sample cloth to our company for comparison test and was satisfied with the test results of the instrument.

6. In July 2016, the instrument was delivered to Guangzhou fiber product testing research institute for use, and the same sample comparison test was conducted with China textile standards (Beijing) inspection and certification center co., ltd. the instrument comparison test passed and passed the expert group acceptance smoothly.

Experts from the acceptance group of Guangzhou Fiber Product Testing Research Institute unanimously confirmed that the far infrared temperature rise tester for textiles developed by our company has high degree of automation, stable performance, accurate test results and good reproducibility.

Testing principle

After irradiating the sample with constant irradiation intensity for a certain period of time on textiles (such as fabrics, nonwoven fabrics, wadding) and other materials, the temperature rise value on the surface of the test surface of the sample is automatically measured.

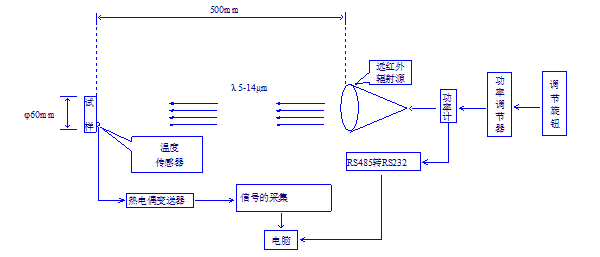

Working principle

The power of the radiation source is regulated to a predetermined power of 150W by a power regulator, and the power of the radiation source is read out by a power meter and transmitted to a PC through a serial port. The sensor that detects the surface temperature of the sample transmits the signal to the acquisition card through the transmitter, and the acquisition card transmits the AD value to the PC. The PC makes corresponding analysis and processing according to the data collected by the sensor.

Technical parameter

1. Sample rack: distance between sample surface and radiation source is 500mm

2. Radiation source: main wavelength 5 ~ 14 μ m, radiation power 150W W.

3. Radiation surface of sample: φ60mm

Instrumental characteristics

The power of far infrared radiation source is monitored by Panasonic power monitoring meter in Japan. High sensitivity temperature sensor detects temperature variation. Quick - change sample loading fixture can easily load samples.

FFZ411 textile far infrared temperature rise tester

Due to the needs of the testing market, Guangzhou Fiber Product Testing Research Institute decided to carry out the testing project of "Textile Far Infrared Temperature Rise Test". Because the national standard GB/T30127-2013 Testing and Evaluation of Far Infrared Properties of Textiles related to this project was promulgated in 2013, at that time, domestic and foreign instrument manufacturers had not yet developed testing instruments that met this standard. After extensive market research and investigation, Guangzhou Fiber Product Testing Research Institute finally decided to cooperate with our company to jointly develop the "Textile Far Infrared Temperature Rise Tester".

1. In July 2015, Guangzhou Fiber Product Testing Research Institute put forward technical requirements for the project;

2. In September 2015, our company issued a technical plan for the instrument.

3. In October 2015, both parties confirmed the technical scheme of the instrument and signed a development contract.

4. The research and development of the instrument was completed in May 2016 and passed the internal inspection of the quality department of the company.

5. In June 2016, Guangzhou Fiber Product Testing Research Institute delivered the test sample cloth to our company for comparison test and was satisfied with the test results of the instrument.

6. In July 2016, the instrument was delivered to Guangzhou fiber product testing research institute for use, and the same sample comparison test was conducted with China textile standards (Beijing) inspection and certification center co., ltd. the instrument comparison test passed and passed the expert group acceptance smoothly.

Experts from the acceptance group of Guangzhou fiber product testing research institute unanimously confirmed that the "textile far infrared temperature rise tester" developed by our company has high degree of automation, stable performance, accurate test results and good reproducibility.

Testing principle

After irradiating the sample with constant irradiation intensity for a certain period of time on textiles (such as fabrics, nonwoven fabrics, wadding) and other materials, the temperature rise value on the surface of the test surface of the sample is automatically measured.

Working principle

The power of the radiation source is regulated to a predetermined power of 150W by a power regulator, and the power of the radiation source is read out by a power meter and transmitted to a PC through a serial port. The sensor that detects the surface temperature of the sample transmits the signal to the acquisition card through the transmitter, and the acquisition card transmits the AD value to the PC. The PC makes corresponding analysis and processing according to the data collected by the sensor.

Technical parameter

1. Sample rack: distance between sample surface and radiation source is 500mm

2. Radiation source: main wavelength 5 ~ 14 μ m, radiation power 150W W.

3. Radiation surface of sample: φ60mm

Instrumental characteristics

The power of far infrared radiation source is monitored by Panasonic power monitoring meter in Japan. High sensitivity temperature sensor detects temperature variation. Quick - change sample loading fixture can easily load samples.